Elisa-3 is a miniature swarm robot with a diameter of 5 cm, featuring auto recharge, fast radio communication, 8 proximity sensors, 4 ground sensors, a 3D accelerometer, and a top RGB LED with a diffuser, designed to be affordable.

Overview

Elisa-3 is an evolution of the Elisa robot based on a different micro-controller and including a comprehensive set of sensors:

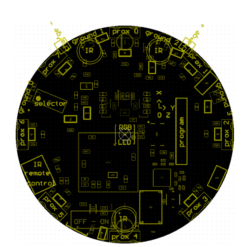

- Atmel 2560 micro-controller (Arduino compatible)

- Central RGB LED

- 8 green LEDs around the robot

- IR emitters

- 8 IR proximity sensors (Vishay Semiconductors Reflective Optical Sensor)

- 4 ground sensors (Fairchild Semiconductor Miniature Reflective Object Sensor)

- 3-axis accelerometer (Freescale MMA7455L)

- RF radio for communication (Nordic Semiconductor nRF24L01+)

- Micro USB connector for programming, debugging, and charging

- IR receiver

- 2 DC motors

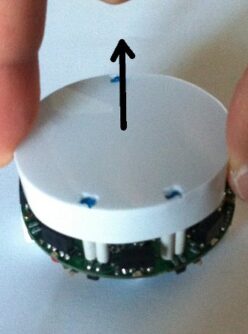

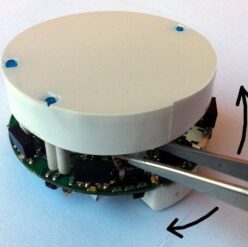

- Top light diffuser

- Selector